In recent years, 3D printing technology has revolutionized the manufacturing industry, offering a wealth of benefits and opportunities for businesses around the world. From rapid prototyping to customized production, 3D printing has transformed the way products are designed, produced, and distributed. In this blog post, we will explore the impact of 3D printing on manufacturing and how it is changing the industry landscape.

One of the most significant impacts of 3D printing on manufacturing is its ability to accelerate the product development process. Traditional manufacturing methods often involve time-consuming and costly prototyping processes, which can slow down the production timeline. With 3D printing, designers can quickly create prototypes and iterate on designs in a matter of hours, rather than weeks. This rapid prototyping capability allows manufacturers to bring products to market faster and more efficiently.

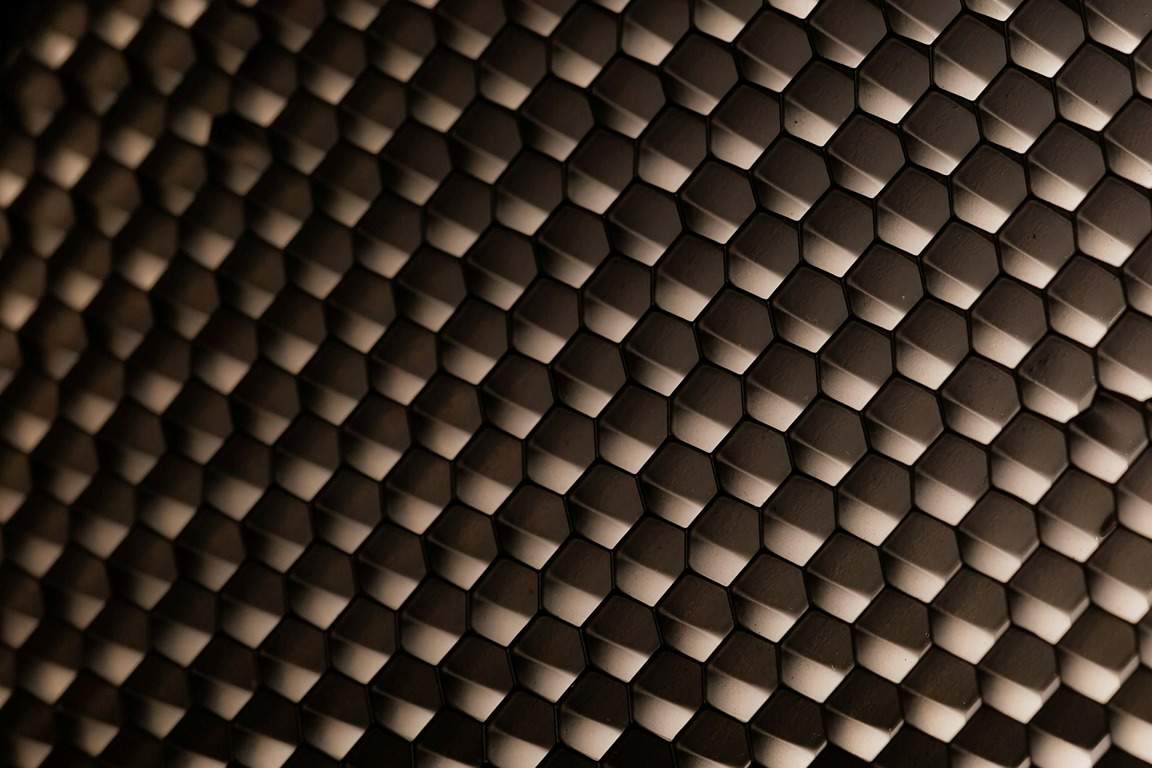

Moreover, 3D printing enables manufacturers to produce complex and intricate designs that would be difficult or impossible to create using traditional manufacturing methods. This level of design freedom opens up new possibilities for product innovation and customization. Manufacturers can create highly customized products tailored to individual customer needs, leading to increased customer satisfaction and brand loyalty.

Another key impact of 3D printing on manufacturing is its potential to reduce waste and minimize environmental impact. Traditional manufacturing processes often result in excess material waste, as well as energy and resource consumption. 3D printing, on the other hand, is an additive manufacturing process that builds objects layer by layer, using only the material required for the final product. This minimizes waste and reduces the environmental footprint of production processes, making 3D printing a more sustainable option for manufacturers.

In addition to its environmental benefits, 3D printing also offers cost-saving advantages for manufacturers. While the initial investment in 3D printing technology may be significant, the long-term cost savings can be substantial. With 3D printing, manufacturers can reduce inventory costs by producing on-demand and eliminating the need for mass production and warehousing. This lean manufacturing approach can result in lower production costs and higher profit margins for businesses.

Furthermore, 3D printing has the potential to transform the supply chain and distribution process. With 3D printing, manufacturers can produce products closer to the point of sale, reducing lead times and transportation costs. This localized production model can improve supply chain efficiency and agility, allowing businesses to respond quickly to changing market demands and customer preferences.

Despite its numerous benefits, 3D printing also presents challenges and limitations for manufacturers. The technology is still relatively new and evolving, and may not be suitable for all types of products or materials. Quality control and regulatory compliance issues can also arise with 3D printed products, requiring manufacturers to implement rigorous testing and validation processes.

In conclusion, 3D printing is transforming the manufacturing industry in profound ways, offering a range of benefits and opportunities for businesses. From rapid prototyping to customized production, 3D printing has the potential to revolutionize the way products are designed, produced, and distributed. While challenges and limitations exist, the impact of 3D printing on manufacturing is undeniable, and businesses that embrace this technology stand to gain a competitive edge in the rapidly evolving marketplace.