The world of manufacturing is constantly evolving, and one technology that is poised to revolutionize the industry is 3D printing. This innovative technology has the potential to completely transform the way products are designed, produced, and distributed.

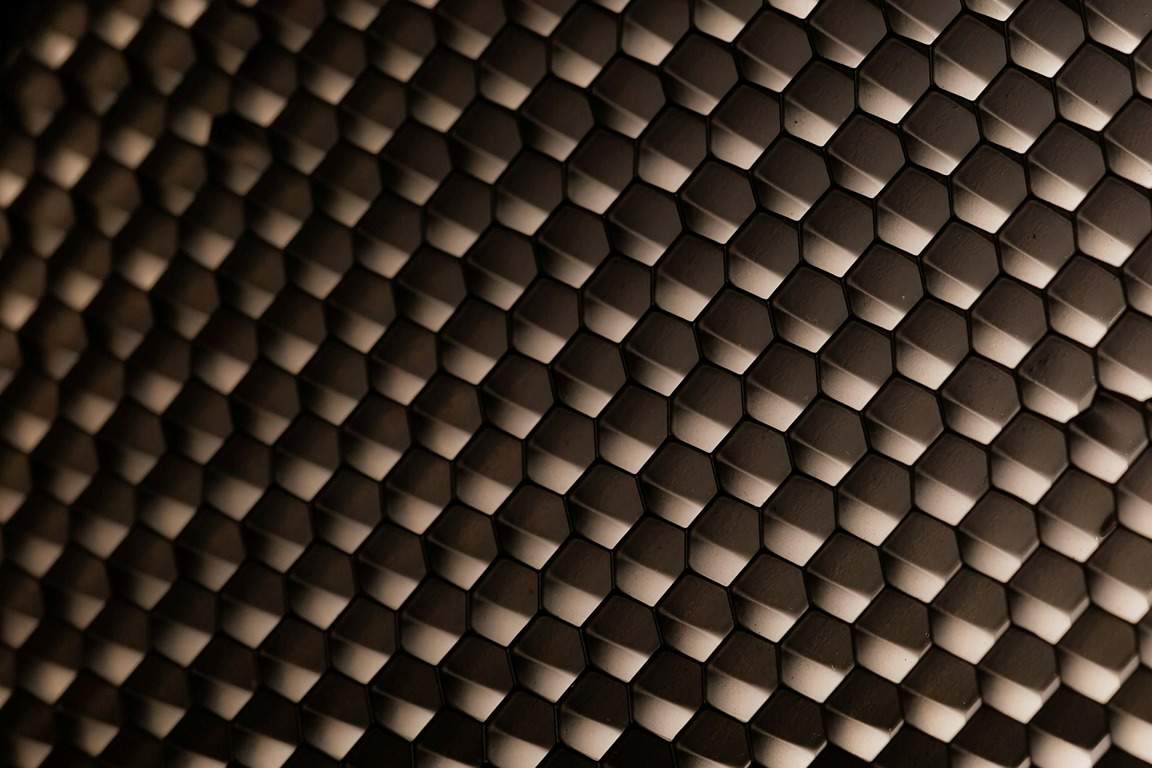

3D printing, also known as additive manufacturing, uses a digital file to create three-dimensional objects by layering material on top of each other. This process allows for the creation of complex shapes and intricate designs that were previously impossible with traditional manufacturing methods.

The future of 3D printing in manufacturing is incredibly bright, with the technology being increasingly adopted by a wide range of industries. From aerospace and automotive to healthcare and consumer goods, 3D printing is proving to be a game-changer in how products are developed and produced.

One of the key advantages of 3D printing in manufacturing is its ability to reduce costs and lead times. Traditional manufacturing methods often require expensive tooling and long production cycles, but with 3D printing, products can be produced more quickly and cost-effectively. This not only saves companies money but also allows for greater flexibility and customization in product design.

Another benefit of 3D printing is its ability to create lightweight and strong structures that are not possible with traditional manufacturing techniques. This has important implications for industries such as aerospace and automotive, where lightweight materials are essential for fuel efficiency and performance.

In the healthcare industry, 3D printing is being used to create customized medical devices, prosthetics, and even organs. This personalized approach to healthcare is revolutionizing the way patients are treated and managed, leading to better outcomes and improved quality of life.

The future of 3D printing in manufacturing is also being driven by advancements in materials and technology. With a wider range of materials becoming available for 3D printing, including metals, ceramics, and composites, the possibilities for product design and production are virtually endless.

Furthermore, ongoing research in areas such as bioprinting and nanotechnology is pushing the boundaries of what 3D printing can achieve. Imagine a future where organs and tissues can be printed on-demand, or where products are designed at the molecular level for maximum performance and efficiency.

As 3D printing continues to mature and evolve, it is clear that the technology will play a pivotal role in the future of manufacturing. Companies that embrace 3D printing now will have a competitive advantage in a rapidly changing industry, and will be well-positioned to capitalize on the numerous benefits that this transformative technology has to offer.