In recent years, there has been a significant shift in the manufacturing industry known as “reshoring.” This phenomenon refers to the process of bringing production back to local economies instead of outsourcing it to overseas locations. Reshoring manufacturing has gained momentum for several reasons, including cost-effectiveness, reduced risks, and the revitalization of local economies. In this blog post, we will explore these factors and discuss why reshoring manufacturing has become a prominent trend in today’s global market.

One of the primary reasons for reshoring manufacturing is the cost-effectiveness it offers. While outsourcing production to countries with lower labor costs may initially seem like a cheaper option, it often comes with hidden expenses. Quality control issues, communication barriers, and longer lead times can contribute to delays and increased costs in the long run. Moreover, rising wages in certain overseas locations have reduced the cost gap between local and foreign labor. Recognizing these challenges, companies have started to reconsider the benefits of domestic manufacturing.

Reshoring manufacturing also helps reduce risks associated with supply chain disruptions. The COVID-19 pandemic exposed the vulnerabilities of global supply chains, as countries went into lockdown and borders closed. Companies relying heavily on overseas production faced significant challenges in sourcing components and raw materials. By bringing manufacturing back to local economies, businesses can avoid these risks and ensure a steady supply of goods. This approach allows for better inventory management, more efficient delivery processes, and increased resilience in times of crisis.

In addition to cost and risk factors, reshoring manufacturing has a positive economic impact on local communities. When companies invest in local production, it creates job opportunities and stimulates economic growth. More job opportunities mean increased household income, which can boost consumer spending and support local businesses. The ripple effect of reshoring manufacturing can be seen in various sectors, including transportation, warehousing, and professional services. Moreover, by revitalizing local economies, companies contribute to a more sustainable and balanced economic development model.

Reshoring manufacturing also offers environmental benefits. Overseas production often involves long-distance transportation, resulting in increased carbon emissions. By reducing the distance goods must travel, reshoring helps lower the carbon footprint associated with transportation. Local manufacturing can also promote sustainable practices and compliance with environmental regulations. With growing global concerns about climate change, reshoring manufacturing aligns with the objectives of achieving a more environmentally friendly future.

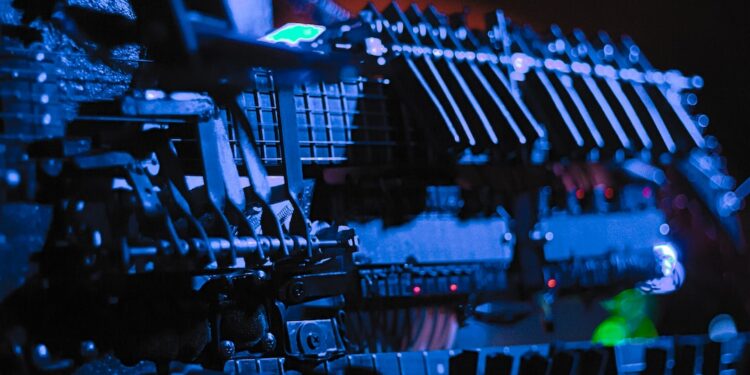

One of the key factors enabling reshoring manufacturing is technological advancement. Automation and robotics are revolutionizing the production process, making it more efficient and cost-effective. By implementing advanced technologies, companies can achieve higher levels of productivity and quality control, reducing the need for extensive manual labor. This shift towards automation not only improves operational efficiency but also promotes the creation of skilled jobs in areas such as robotics programming and maintenance.

Despite the numerous advantages, reshoring manufacturing still faces challenges. One obstacle is the need for skilled labor. As production becomes more technologically advanced, businesses require workers with specialized skills and knowledge. Ensuring a well-trained workforce will be crucial to fully realize the benefits of reshoring manufacturing. Collaboration between educational institutions, industry associations, and government authorities is essential to address this challenge successfully.

Another challenge is the cost associated with reshoring manufacturing. Investment in new infrastructure, updated facilities, and advanced technologies can be a significant financial burden for companies. Government incentives and support programs can play a vital role in encouraging reshoring and mitigating these costs. Policy changes that promote domestic manufacturing, such as tax breaks or reduction in regulatory burdens, can create a favorable environment for companies to reshore their operations.

In conclusion, reshoring manufacturing is a growing trend driven by various factors such as cost-effectiveness, reduced risks, and economic revitalization. The shift towards reshoring has been facilitated by advancements in technology and automation. By bringing production back to local economies, companies can reap numerous benefits, including improved cost control, reduced supply chain risks, and a positive impact on local communities. However, challenges such as skilled labor availability and initial investment costs must be addressed to fully embrace reshoring manufacturing.