How to Improve Product Quality with Automated Inspection Systems

In today’s highly competitive global market, ensuring product quality has become paramount for businesses across various industries. With customers becoming more discerning and demanding, it is crucial for companies to invest in technologies that can improve the quality of their products. One such technology that has gained significant traction in recent years is automated inspection systems.

Automated inspection systems utilize advanced technology to assess the quality of products during the manufacturing process. These systems perform a range of functions, including defect detection, dimensional measurement, and overall quality assessment. By integrating these systems into their production lines, businesses can enhance product quality, increase productivity, and reduce the likelihood of costly recalls.

One of the key benefits of automated inspection systems is their ability to detect defects and irregularities that may not be visible to the naked eye. Traditional inspection methods often rely on manual labor, which can be prone to errors and inconsistencies. On the other hand, automated systems use high-resolution cameras and sophisticated algorithms, enabling them to identify even the slightest imperfections in products. This level of precision and accuracy ensures that only flawless items make it to the market, significantly enhancing customer satisfaction.

Furthermore, automated inspection systems can perform real-time monitoring of production processes, allowing for immediate corrective actions. With the capability to analyze data in real-time, these systems can detect deviations from desired specifications promptly. For instance, if a product’s dimensions are outside the specified range, the system can automatically stop the production line, preventing the defective items from being manufactured further. By catching and addressing issues early on, businesses can avoid unnecessary wastage of resources, including materials and time.

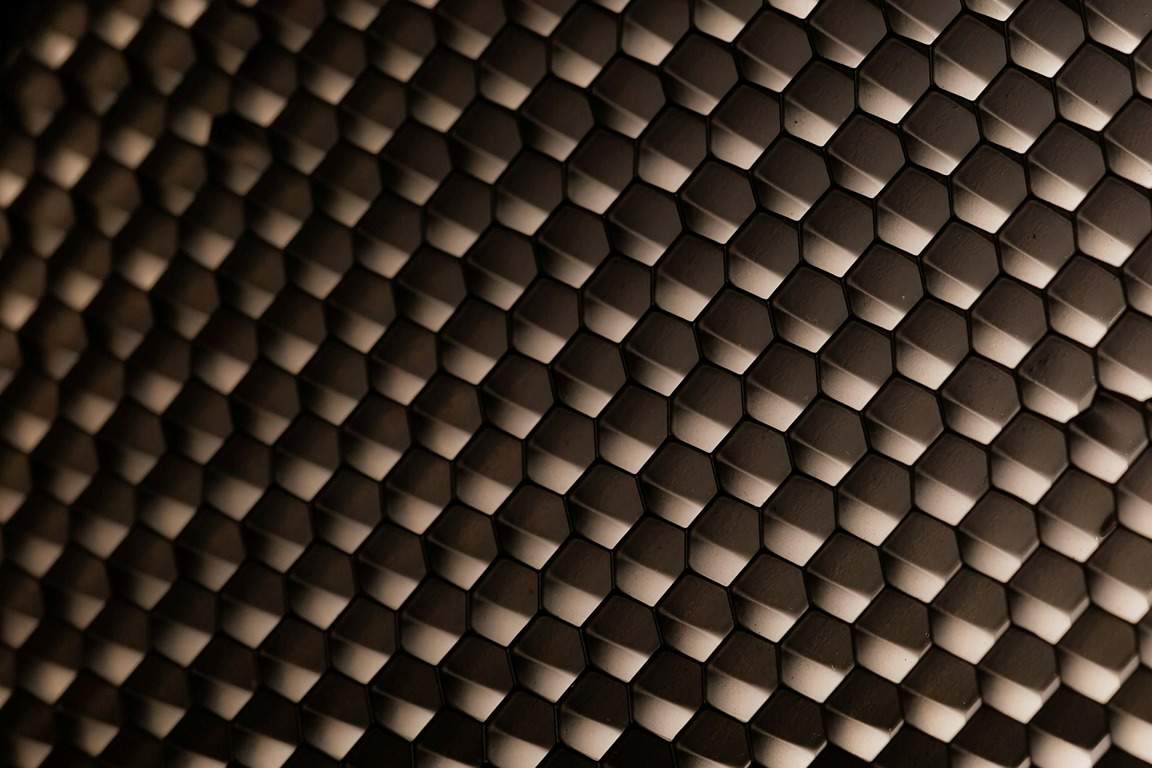

Another advantage of automated inspection systems is their ability to provide valuable data and analytics. Through continuous monitoring and data collection, these systems generate comprehensive reports that offer insights into product quality trends, potential areas for improvement, and overall process efficiency. By studying this data, businesses can make informed decisions regarding production optimization and identify areas where further quality improvements can be implemented. In the case of the keyword “schalldämmung“, automated inspection systems can capture data related to noise insulation materials to ensure their effectiveness and compliance with industry standards.

In conclusion, automated inspection systems have become indispensable for businesses looking to improve product quality in today’s highly competitive market. By utilizing advanced technology, these systems can detect even the slightest defects, allowing for immediate corrective actions. They also provide valuable data and analytics, enabling businesses to continually enhance their production processes. With the keyword “schalldämmung” being relevant to noise insulation materials, automated inspection systems can play a crucial role in ensuring their effectiveness and compliance. Investing in these systems not only helps businesses meet customer expectations but also enhances their reputation and competitive edge in the marketplace.

************

Want to get more details?

TAL Systemtechnik GmbH

https://www.tal-systemtechnik.de/

+49 7731 68405

Byk-Gulden-Straße 36, 78224 Singen

TAL Systemtechnik GmbH – Wir produzieren und liefern Ihnen konfektionierte Dämmstoffe nach Maß, Akustische Dämmung zur Schallisolierung, den TL flexibler Abgasschlauch hitzebeständig und diverse Schallschutzvorhänge für die Industrie.