The Importance of Quality Control in OEM Bag Manufacturing

In the competitive world of OEM bag manufacturing, maintaining high-quality standards is crucial for success. With countless brands vying for consumer attention, it becomes essential for manufacturers to pay meticulous attention to every component and aspect of bag production. Implementing a strong quality control system ensures that the final product meets customer expectations and enhances brand reputation.

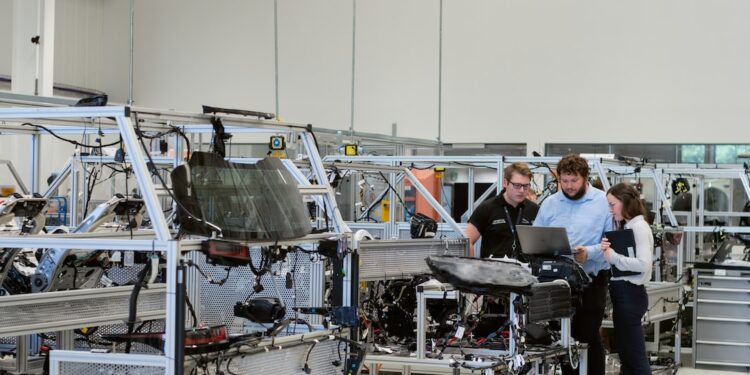

OEM (Original Equipment Manufacturer) bag manufacturing involves the production of bags for various brands and retailers, following their specific requirements and designs. The process typically involves multiple stages, including material sourcing, designing, cutting, stitching, and finishing. At each step, quality control measures must be implemented to maintain consistency and perfection.

One of the primary reasons why quality control is vital in OEM bag manufacturing is customer satisfaction. When brands outsource their bag production, their reputation is at stake. A single flaw or defect in a finished bag can tarnish the brand’s image, leading to customer dissatisfaction and potential loss of sales. By ensuring rigorous quality control measures are in place, manufacturers can deliver bags that are free from defects, meet the brand’s specifications, and provide a positive customer experience. This enhances customer loyalty and contributes to long-term brand success.

Moreover, maintaining quality control in OEM bag manufacturing is essential for cost optimization. Identifying and rectifying defects at early production stages saves both time and money. By catching any issues early on, manufacturers can avoid producing faulty bags in large quantities and prevent costly reworks or product recalls. This also minimizes wastage of resources and streamlines the overall manufacturing process.

Effective quality control in OEM bag manufacturing also helps in building strong partnerships with brands. By consistently delivering high-quality bags, manufacturers can gain the trust and confidence of their clients. This leads to long-term collaborations and repeat orders, benefiting both parties involved. A reputation for producing top-notch bags through quality control measures can open doors to new business opportunities and partnerships with other prominent brands.

To implement quality control effectively, various aspects must be considered. These include material inspection, proper equipment maintenance, regular employee training, and adherence to safety standards. By paying attention to each of these aspects, manufacturers can ensure that every bag produced meets the required quality standards.

In conclusion, quality control plays a pivotal role in OEM bag manufacturing. By emphasizing quality throughout the production process, manufacturers can produce bags that satisfy customer expectations, enhance brand reputation, and optimize costs. Moreover, maintaining strict quality control measures leads to strong partnerships, fostering long-term business growth and success. In an increasingly competitive market, manufacturers should prioritize quality control to remain at the forefront of OEM bag manufacturing.

************

Want to get more details?

Orient Bag

https://www.orientbag.net/

Orient is a manufacturer (OEM) of bags, with production facilities in China, Cambodia and Myanmar. We are a direct factory group making backpacks, school bags, laptop bags, tote bags, tactical gear, gun cases, tool bags, makeup bags and much more.